What’s New in SOLIDWORKS 2022 – Detailing Mode and Drawing Performance

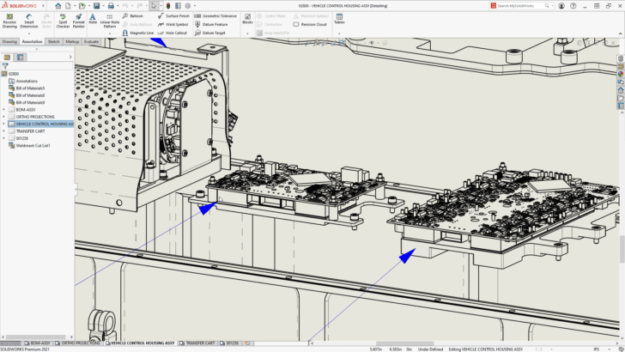

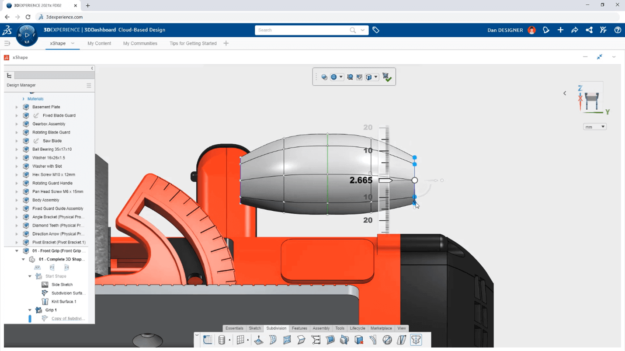

Improvements in the drawing environment are always among the most popular enhancements with the SOLIDWORKS® user base, and SOLIDWORKS 2021 is no exception. Drawing Performance of Solidworks When working with large assembly drawings, view manipulation is vital to a good user experience. Over the years, SOLIDWORKS has steadily optimized users ability to manipulate views. The Enhanced Graphics Performance option, implemented in SOLIDWORKS 2020 to take advantage of high-end graphics cards by moving the graphics burden to the card, has been extended to the drawing environment in SOLIDWORKS 2021. For years, the SOLIDWORKS development team has increasingly raised the bar for performance. This is evident in pairing the Enhanced Graphics Performance option with modern OpenGL 4.5 graphics cards in SOLIDWORKS 2021. Check out this side-by-side comparison between the drawing performances of SOLIDWORKS 2020 and 2021. Detailing Mode of Solidworks With Detailing Mode, users can open massive drawings in seconds. But you can go one step further and edit existing annotations such as notes and dimensions with full access to all the annotation editing tools. In addition, Detailing Mode for Drawings has been enhanced to support the creation of Detail, Break, and Crop views. All of the break line styles, as well as the gap between the breaks, are available. It is common to define Hole information when detailing drawings. Now Detailing Mode supports Hole Callouts. And foreshortened dimensions are applied when necessary. Existing dimensions now have full editing capability. All dimension properties are now available, too, including its Tolerance and Precision. Controls on every tab of the Dimension Property Manager are now available so that you can define the dimension’s arc condition to the center of the hole. VDA balloons are frequently used in the German automotive industry and are a requirement for many European customers. A new leader type is now available for balloons and notes to allow users to tag inspection points per VDA requirements. Position and rotation are easily manipulated, and these VDA balloons can be used directly by SOLIDWORKS Inspection. When working with sketch geometry on a drawing, it is common to add relations just as you would in the sketch environment. Previously, these relations were in the property manager, but now in SOLIDWORKS 2021, the Sketch Relations pop-up toolbar is available, allowing you to apply sketch relations with minimal mouse travel.