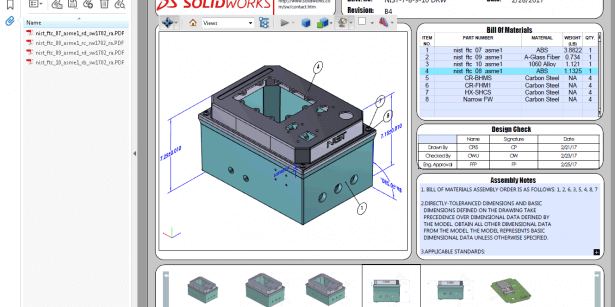

USE OF SOLIDWORKS EXPLORER

What is SOLIDWORKS Explorer SOLIDWORKS Explorer is a very useful tool that helps you in performing work like rename, replace and copy SOLIDWORKS documents. You can also see references, documents in various ways and you can locate all the places where documents are used. You can use the files for the renaming of those documents…