The 3DEXPERIENCE WORKS® Simulation portfolio includes the ability to simulate the metal-forming process. The products can be leveraged on SOLIDWORKS® models when connected to the 3DEXPERIENCE platform.

Forming processes may include stamping, punch stretching, forging, drawing, and more. Truth be told, simulating forming processes can be a difficult task. Usually, they involve geometric, material, and contact nonlinearities.

However, simulation of forming processes offers advantages that outweigh the difficulties. Forming simulations can reduce both the cost and length of a product development cycle by identifying potential problems prior to tooling or fabrication.

Simulation can also improve the quality of the part being manufactured through testing to ensure that the manufacturing processes appropriately account for spring back, stretching of the parts, and thickness reduction.

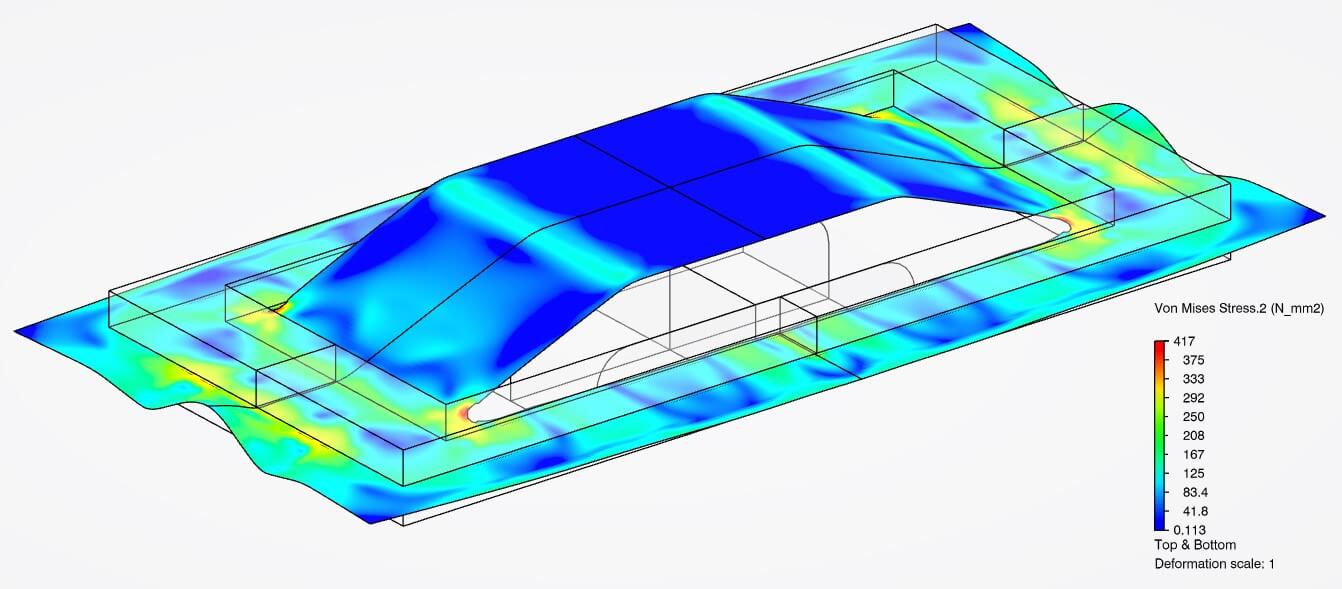

Figure 1: Forming a flap into a sheet metal part

Validate on the Fly

Forming simulation tools on the 3DEXPERIENCE platform recreate manufacturing processes virtually to check for potential problems such as thinning, wrinkling, or cracking. This enables you to adapt on the fly during development, which often eliminates the need for multiple physical prototypes. Plus, you can experiment with different kinds of materials to see how they will behave in the real world (virtually) and then decide which material works best for your application based on actual performance. Also, you can test process parameters such as manufacturing speeds or temperature levels.

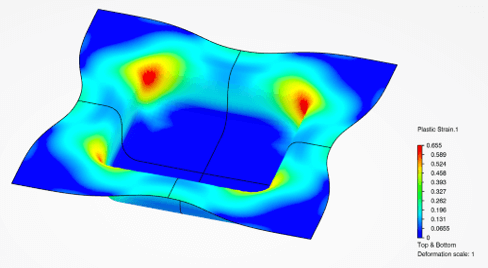

Costly Physical Testing Cycle

In a traditional production environment, without metal forming simulation, you must develop physical tools along the way to validate your design. And this process may require several iterations before getting to a final version—a very slow and expensive process to be sure. However, finite element analysis (FEA) testing shows you how your products will perform, without ever doing a physical test. You can eliminate iteration cycles since you can test designs and materials to validate what will happen during the forming process.

Figure 2: General development process supported by FEA

Figure 2: General development process supported by FEA

Simulation Tool Belt

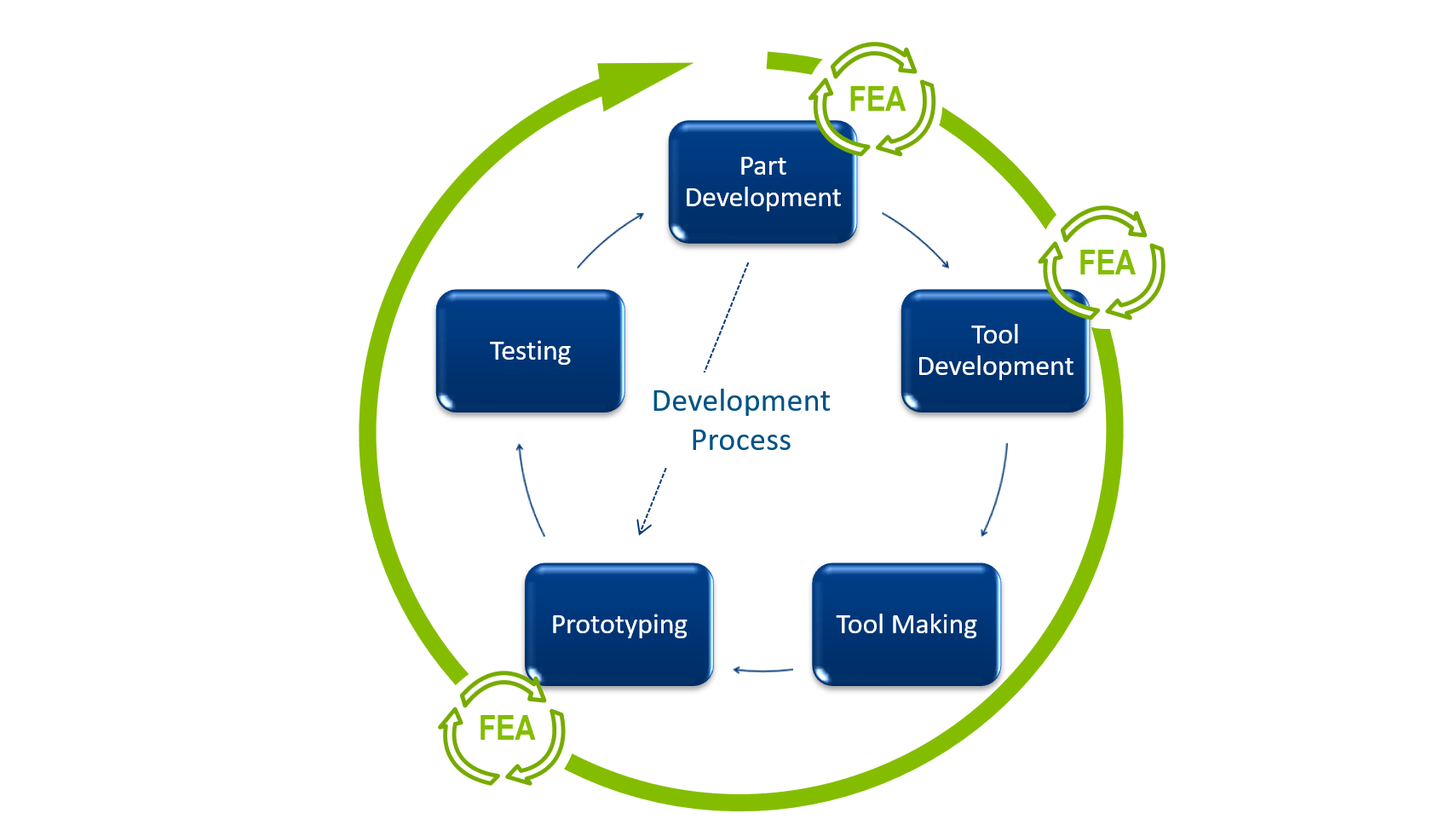

Metal forming simulations are numerically challenging because you will often see large deformations, plasticity, or complex contact situations (with large sliding interactions and friction) which makes for highly nonlinear simulation studies.

The 3DEXPERIENCE WORKS portfolio of simulation solutions provides additional tools for your FEA tool belt. When you encounter simulations in SOLIDWORKS that demand a deeper level of nonlinear studies, you can simply reach for another tool, in this case, the explicit solver within 3DEXPERIENCE to validate forming processes that will increase the efficiency and speed of your product development process.

If you would like more information about simulation for metal forming processes, please contact.

Figure 3: Plastic strain result of a deep drawing simulation

Click here to watch the forming simulation technical webinar that will walk you through the part development process and demonstrate how forming simulation recreates the manufacturing process virtually. If you would like more information about simulation for metal forming processes, please Contact Us.