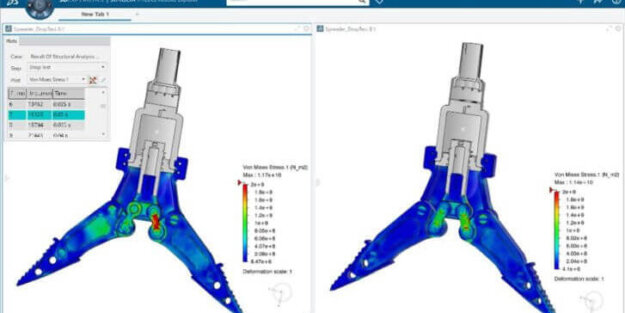

New Seamless SOLIDWORKS Workflow with Proven Advanced Simulation (Abaqus) and Faster Collaboration

When I was a teenager in the late 80s, I was interested in photography (these days referred to as old-school photography). I bought my first camera, a second-hand Minolta SRT, all manual, without electronics and automation. It was a high-quality product. Taking a good photo was an art, as it took time and skill to…