How SOLIDWORKS Helped Build A Belly Racer?

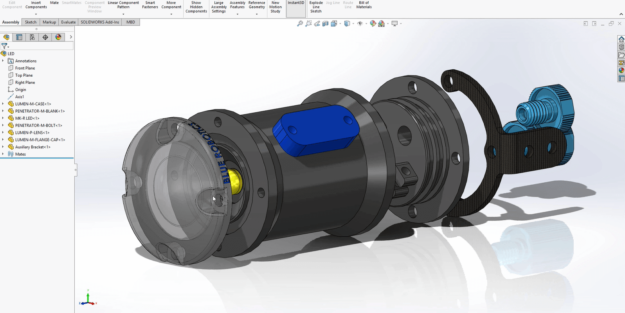

If you have read any of my blogs about the Tucker Torpedo, racing at Indianapolis, or the Tucker Carioca you know that I’m a car guy. For those that didn’t read those blogs and just so you know; I’m a car guy. I jump at the chance to work on, rebuild, customize, race and thoroughly enjoy cars in all forms. One of my favorite time periods is 1930 to 1960. During these years hot rods were created. After WWII men came back home with specialized knowledge about high-performance engines from being aircraft mechanics. And the pilots who were adrenaline junkies needed to go fast but didn’t have an airplane anymore to satisfy that need. So they turned to cars, and this is what this blog series is about. The men and women who took the know-how and need for speed to turn war surplus aircraft parts into cars were known as “Belly Racers.” These were land speed record cars, not your typical race cars you see on TV. These were small, light and fast, but they also have their downsides. Like all auto racing, it’s a dangerous sport and this was especially the case back in the 1940s when safety was secondary to going fast. The Belly Racer got its name from the auxiliary fuel tanks used on aircraft during WWII, which provided additional fuel for extended flights. What you might have thought of as a deployable bomb under the fuselage of an airplane in war movies was instead a belly tank. The tank could be dropped at any time by the pilot if needed. Here’s a good picture of a belly tank that can hold several hundred gallons of fuel. After the war, the aux tanks or “Belly” tanks were no longer needed and considered war surplus. The pilots and aircraft mechanics probably bought the belly tanks at their local Army/Navy store and turned them into land speed racers using their hot rod knowledge. Back in the late 1940’s drag racing was just getting started in California and that wasn’t what they wanted to do. They wanted to go as fast as the planes they flew. So they turned to land speed racing, which had been around for several decades starting with Henry Ford when he covered the mile in 39.4sec at an incredible 91.37MPH. Quite an accomplishment back in 1903. A belly tank was an easy choice to make if you’re going to build a land speed racer; it’s aerodynamic and light. Knowing this going in when building a land speed racer takes a lot of guesswork out of coming up with a shape that has a minimal drag coefficient. But the aerodynamic shape does pose packaging challenges. A driver, engine, cooling system, suspension, driveline, and fuel tank all have to fit inside the belly tank. These challenges didn’t thwart the guys who were building these racers. They were very ingenious and resourceful. Their accomplishments in the garage building and developing the belly racer were as satisfying as the accomplishments on the salt flats where they raced. Here in the U.S. land speed records have been made on the beaches of Daytona Beach, Florida, the Bonneville Salt Flats, Utah, and at Black Rock, Nevada, where the land speed record was set at 763MPH in 1997 by the Thrust SSC! Bonneville is the oldest and most famous site for land speed records starting in 1912. Both Bonneville and Black Rock offer an almost unlimited area to hold land speed races because it takes 11 miles of flat open area to set a speed record. As a racer, you have five miles to get up to speed before entering the timed mile then five miles to slow down. In order to set a land speed record, the car must make a return run within an hour and cover the same 11 miles. The average of the two runs determines the land speed record. There are many YouTube videos to watch on Bonneville land speed record racing. Watch a couple if you can you will be entertained and impressed by the engineering involved to go fast. Attending Bonneville is on my bucket list to attend because I’m a car guy and an engineer. Some of the coolest purpose-built race cars are can be found at Bonneville including Belly Racers like these: This is what a Belly Racer looked like back in the 1940s. The Idea Of Building A Belly Racer In SOLIDWORKS Came from a British chap, Paul Cameron. Paul and I crossed paths because of the Carioca project and have become friends because of our mutual love of cars. Paul reached out to me about a year ago and asked if I was interested in helping him with his Belly Racer project. What do you think my answer was?