SOLIDWORKS Simulation 2022: Enhanced Contact for Faster, More Stable and Accurate Results

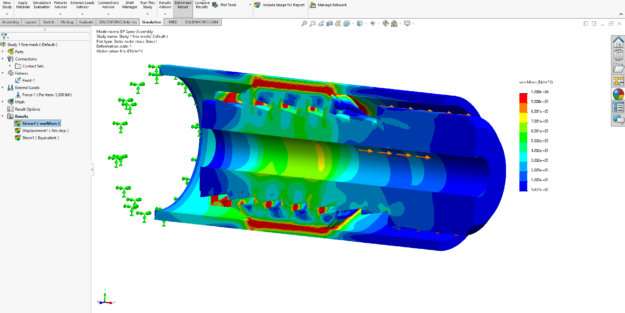

SOLIDWORKS Simulation 2022 is the biggest release we have seen in many years! We remain focused on making Simulation easier and faster for SOLIDWORKS users to apply to their designs. With the enhanced 2022 Simulation features, you can design better products faster than ever before. Better Performance: Faster Contact Simulation SOLIDWORKS Simulation 2022 calculates contact interactions significantly faster than previous versions. Solution time is improved by using parallel multicore computing, better CPU usage, faster stiffness calculation, and robust data communication for contact pairs. Designers will notice considerable benefits in models with numerous contact interactions. Benchmark data performed by our developers and by reseller Computer Aided Technology (CATI) show performance improvements ranging from 25% to 67%. Fig 1. A simulation model with numerous contact elements Easier Simulation: Contact Stabilization Many CAD models have less than perfect geometries, such as non-touching surfaces or clearance between bodies. These design elements make it more difficult for the solver to get started, which in turn prolongs solving time. SOLIDWORKS Simulation 2022 Contact Stabilization enhancement resolves this issue. Contact Stabilization works by adding a small numerical stiffness value to qualified areas before they come into contact. With contact stabilization, the solver can resolve instability issues encountered at the start of the solution before contact is initiated, and designers can more easily obtain Simulation results. You may be wondering: How do I take advantage of this enhancement? That is the best part of this story! The software automatically applies contact stabilization when your geometries have an initial clearance. This new feature is part of our Robust Default initiative, which uses Default Settings where the software fills out most settings, and the users only need to change custom fields. Fig 2. Contact model with initial clearance Improved Accuracy: Better convergence and more realistic contact representation between curved surfaces When meshing components, it is difficult to capture the exact gap distance between curved surfaces, especially when a coarse mesh and/or draft elements are being used. With SOLIDWORKS Simulation 2022, the software automatically calculates the geometry correction terms, which improve the representation of curved surfaces of cylindrical, spherical, and conical geometries. These terms are then used to improve the accuracy of the simulation results for curved surfaces. This capability has been implemented through collaboration with our sister brand SIMULIA which specializes in simulation. Fig 3. Contact interaction between curves surfaces New Feature: Improve Mesh Quality with a New Set of Mesh Diagnostic Tools A high-quality mesh is a key to a good simulation for result accuracy, convergence, and calculation speed. SOLIDWORKS Simulation 2022 introduces a brand-new set of diagnostic tools that enable you to examine the quality of a mesh by identifying and isolating poor quality elements and then prompting you to fix them. The Mesh Quality Diagnostics Tool can be used to display Aspect Ratio, Jacobian Ratio, etc. You can then use the Mesh Helper to get assistance refining the mesh in key areas and resolve mesh quality before proceeding to solve your analysis. Fig 4. Poor quality elements identified by the new Mesh Diagnostics Tools New Mesh Default: No Enforced Common Nodes In 2022, we made No Enforced Common Nodesthe default to make it easier and faster to mesh large and complex assemblies. In SOLIDWORKS Simulation 2022, we continue to make improvements in this area by increasing the accuracy of results in Simulation scenarios where gaps or small interferences exist due to the meshing process. A typical example is when using shell elements, the gap is due to the shell thickness. Fig 5. No Enforced Common Nodes solid mesh SOLIDWORKS Simulation 2022 enhancements demonstrate real-world user benefits, making it easier and faster than ever for SOLIDWORKS users to get accurate simulation results. We continue to build as much automation into the software as possible, so it does more of the simulation work for you. In turn, you can minimize design time and maximize speed to market. To get more information or schedule a demo of SOLIDWORKS Simulation 2022