SOLIDWORKS® 2022

Introduces many enhancements that add to its already robust capabilities when working with parts, including enhancements to sheet metal, 3MF support, and weldments. For a comprehensive list of enhancements, see What’s New in SOLIDWORKS 2022.

Sheet Metal – Edge Flange Capabilities

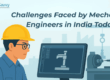

Now when working with sheet metal parts in SOLIDWORKS 2022, edge flanges can be created on curved edges originating from non-planar faces such as those in the bend area, as in the image below

The preview shows how the edge flange will be created all the way around the part. Familiar flange customization tools are available to help define the length, angle, flange length dimensioning method, and flange position. This edge flange can also be flattened to prepare it for detailing or exporting to DXF for fabrication.

The preview shows how the edge flange will be created all the way around the part. Familiar flange customization tools are available to help define the length, angle, flange length dimensioning method, and flange position. This edge flange can also be flattened to prepare it for detailing or exporting to DXF for fabrication.

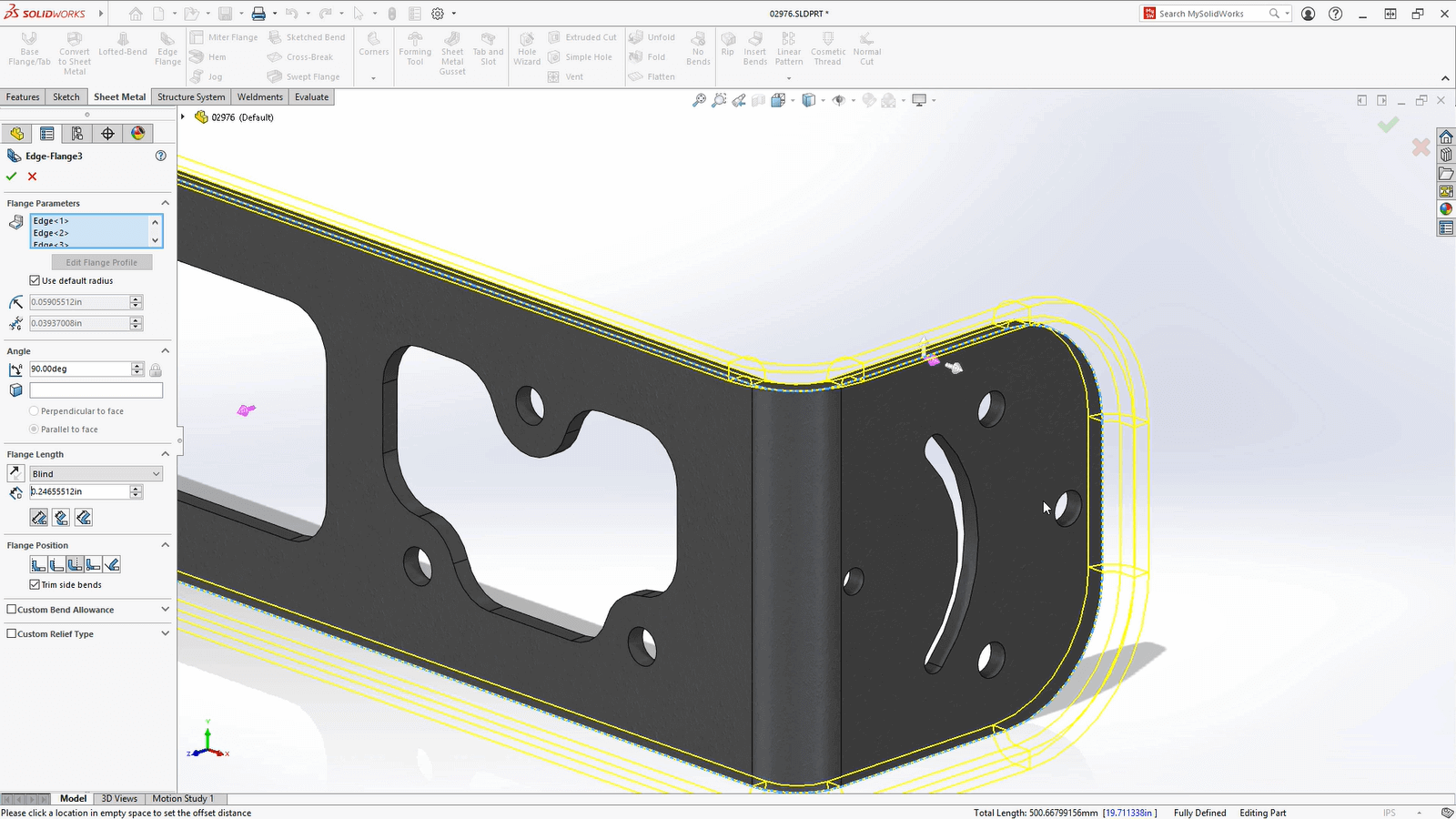

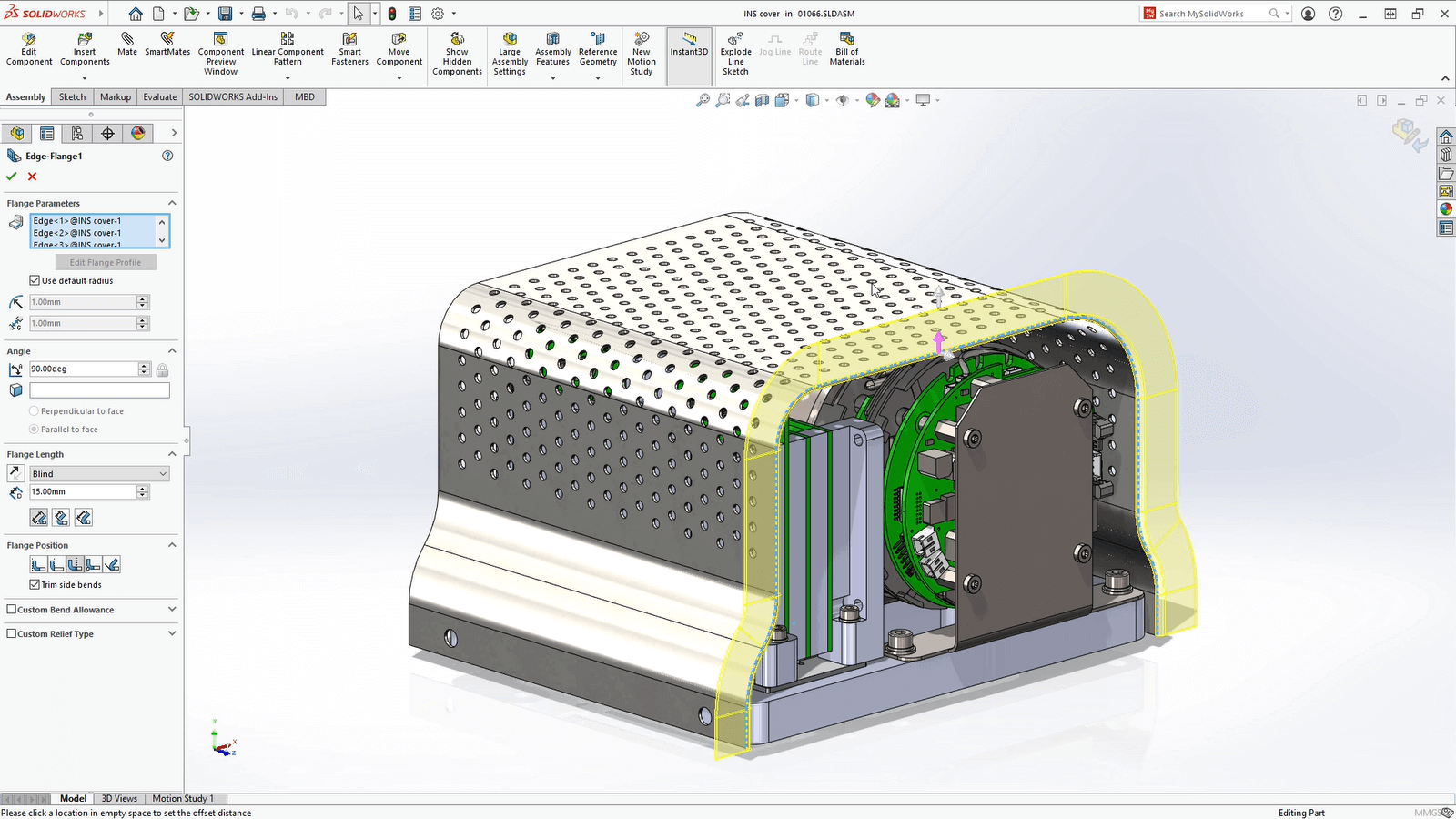

The edge flange is great for structural integrity and is also useful for enclosure and guarding, such as in the cover shown in the image below.

The edge flange on the far side needs to protect the components of this navigation control unit. With full editing capabilities, we can change the direction of the flange, as well as the angle, to wrap around the internal components to keep them safe.

The edge flange on the far side needs to protect the components of this navigation control unit. With full editing capabilities, we can change the direction of the flange, as well as the angle, to wrap around the internal components to keep them safe.

This new edge-flange capability along non-linear edges extends the robust sheet metal capabilities of SOLIDWORKS 2022 for many applications such as adding stiffing ribs and enclosures.

Enhanced 3MF Support

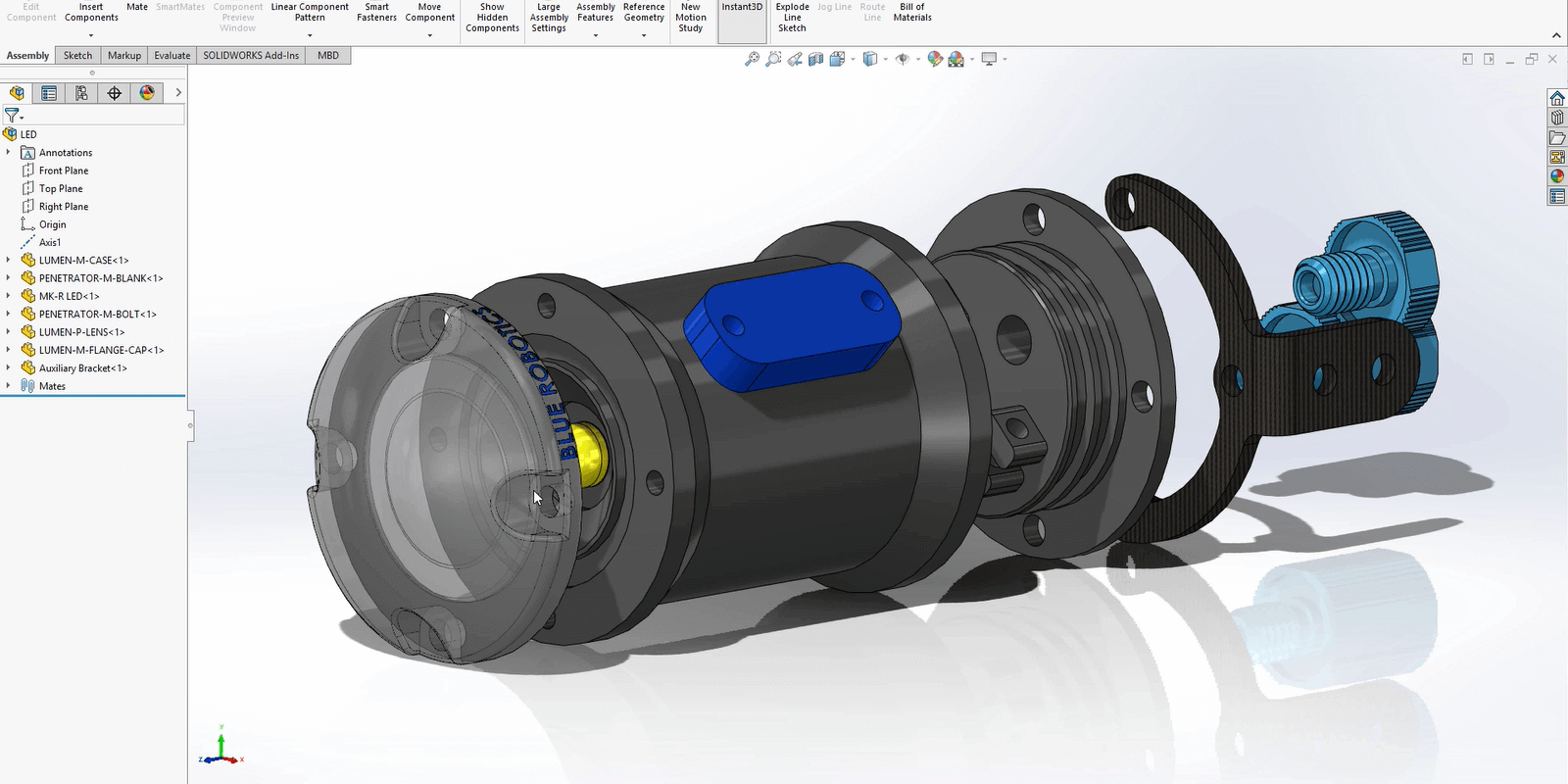

Support for the export and import of 3MF files is even better in SOLIDWORKS 2022. Now color, textures, and transparency are supported on export, and this information is stored in the 3MF file to be used for manufacturing or other applications. For example, the LED light assembly in the image below contains various colors, applied textures, and transparency and needs to be 3D printed.

Additive manufacturing continues to rise in capability and popularity, and SOLIDWORKS continues to embrace these technologies. More views are now supported when opening 3MF files in SOLIDWORKS 2022. Per-facet and per-vertex coloring, as well as textures and transparency, can now be visualized when importing 3MF files as graphics bodies.

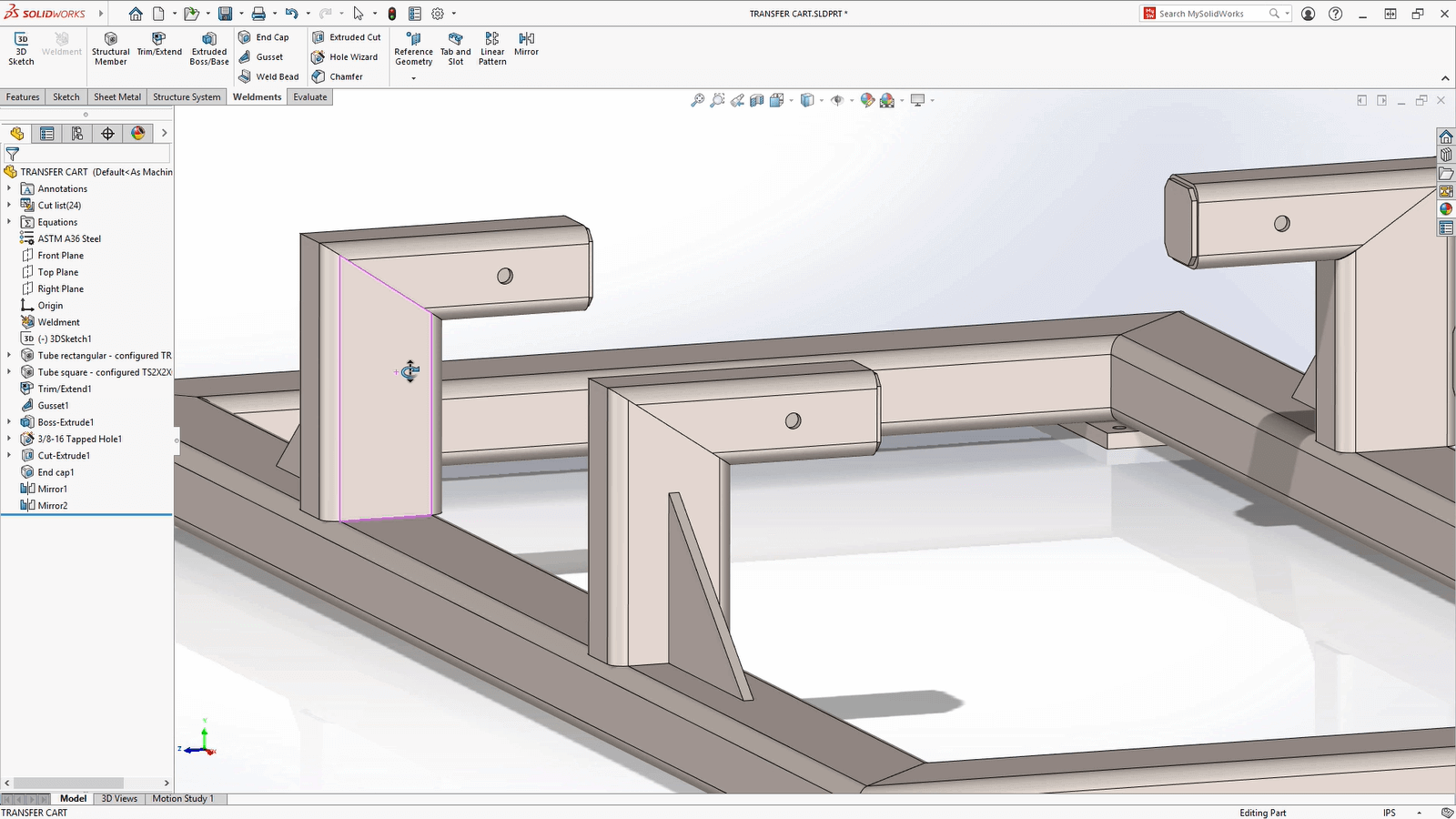

Weldments – Flush Miter

It is common to use various sizes of weldment members when working in the weldment environment. For example, the horizontal tubes depicted in the welded frame below are 2 x 2 square tubes, and the vertical tubes are 3 x 2 rectangular tubes.

The weldment Trim/Extend tool is used to trim the tubes to each other, with various options for the corner type. The two end butt trims dictate how one tube trims to the other, and the mitered trim bisects the angle between the two tubes, creating an equal angle miter trim. Since these tubes are of different profiles, the equal angle miter does not produce the desired result.

The weldment Trim/Extend tool is used to trim the tubes to each other, with various options for the corner type. The two end butt trims dictate how one tube trims to the other, and the mitered trim bisects the angle between the two tubes, creating an equal angle miter trim. Since these tubes are of different profiles, the equal angle miter does not produce the desired result.

There’s a new option for Miter trims in SOLIDWORKS 2022, the Flush Miter, which does just that. It trims the tubes so they meet flush. The other vertical members are mirrored, so they update as well.